Customer Profile

A Large International Mining Equipment OEM for Ball and AG/SAG Mills

Application

Open Gear Lubricant Spray System to service a Ball Mill with a gear width of

970mm.

Issue

The previously used lubrication system only allowed the monitoring of the

air pressure to the spray valves and grease pressure in the mainline of the

Dual Line lubrication system. Unfortunately, this type of system does not alert the

plant operator if one or more of the eight dual line distributor valves are

malfunctioning or blocked.

With a large gear set like this the lack of an adequate boundary lubrication

layer could be disastrous leading to excessive wear and flank damage.

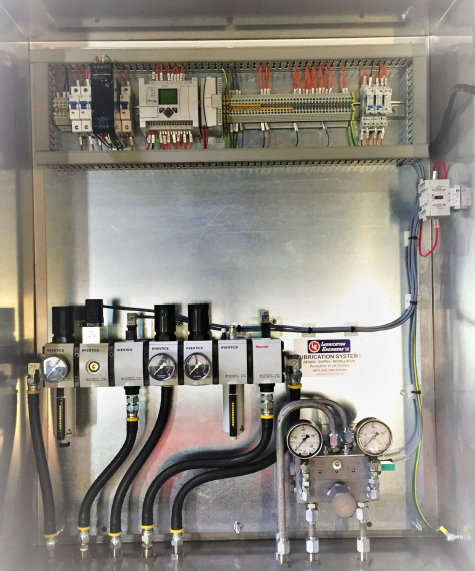

Lubrication Engineers Solution

Lubrication Engineers Australia redesigned the system to include the features

of a Bijur Delimon DR-4 Hydraulic Reversing Valve with operation of the internal

piston, monitored via a proximity switch, eight SDM Modular Dual Line valves

which are adjustable from 1-10 cc. Each valve is fitted with a proximity switch

to allow individual monitoring and a PLC is used to monitor all 12 inputs and 6

outputs.

The PLC, alarm warning lights, DR-4 Reversing valve and the Bosch modular air

control which includes two air solenoid valves, one air pressure switch, two air

regulators and lubricator are all housed in a stainless steel enclosure.

Results

The design of this system has now been adopted for all new and refurbished

open gear lubrication systems by the OEM.