Overview

Lubrication Engineering are an Australian owned and operated, premier supplier of high-performance lubricants, reliability solutions and lubrication technology.

We have a proven ability to both design and deliver solutions that meet the performance, reliability and technological expectations of the broader industry while maintaining exceptional levels of service and support across Australia. Our solutions utilise a holistic view of the actual performance requirements and take into consideration all aspects of the lubrication circle of reliability.

Australian Industry capability includes:

- Design

- Manufacture

- Assembly

- Installation

- Testing

- Project Management

- Contract Management

- Administration

- Warehousing & Spare Stock

- Technical Support

- Service Support

- Upgrades and Replacements

All of our solutions incorporate the ‘Circle of Lubrication Reliability’ providing;

Minimum Downtime:

We know that the cost of downtime outweighs the cost of repair. We enable plants and equipment to keep working with minimum downtime.

Energy Savings:

Low friction, smooth running equipment utilises less energy – a major operating cost for most organisations.

Longer Equipment Life:

Ensuring high cost capital equipment lasts longer, minimising wear and corrosion, while substantially reducing parts and labour costs.

Longer Lubricant Life: Lubrication Engineering’s products last longer than competitors in the market with long-term costs, and overall downtime for routine maintenance reduced.

Improved WHS:

Automatic Lubrication Systems reduce the potential of risks associated with manual lubrication by reducing personnel interactions with machinery.

ISO Certification

Lubrication Engineering are dedicated to delivering quality products and services.

We are committed to continuous improvement and have the following ISO Certification to provide our customers piece of mind.

- ISO 9001 (Quality Management)

- ISO 14001 (Environmental Management)

- ISO 45001 (OHS Management)

- ISO 27001 (Information Security Management)

Industries Served

- Oil & Gas

- Automotive

- Power Generation

- Transport

- Minerals Refining

- Defence

- Marine

- Agriculture

- Petro Chemical

- Heavy Industry

- Food & Beverage

- Hard Rock Mining

- Coal Mining

- General Manufacturing

Products and Services

- Lubrication Technology

- Lubrication Equipment

- Automatic Lubrication Systems

- Contamination Management

- Specialty Lubricants

- Reliability Solutions

- Consultation

- Lubrication Maintenance

- Training

- Auditing

- Storage & Dispensing

Facilities and Equipment

- Head office and Workshop in NSW

- National Sales Support

- National Technical Support

Major Clients

- Rio Tinto

- BHP Billiton

- Liberty (Onesteel)

- InfraBuild

- Australian Submarine Corporation

- Newmont

- Queensland Alumina Limited

- Arnott’s

- Boral

- Inghams

- BMA

- AGL Generation

- Bega

- Maersk

- EMAS

- Fugro

- SAIPEM

- THENAMARIS

- Nyrstar

- Snowy Hydro

- AGL

- Engie

- Takraf Tenova

- Newcrest Mining

- Bluescope Steel

Significant Projects

National Recycling Company Implements isoPOD Lubrication Storage and Dispensing System

Design and supply seven IsoPOD® Lubrication and Dispensing systems, providing a portable, best practice solution for lubrication storage, contamination management and dispensing.

Each IsoPOD® system provides clean, compliant, safe, efficient storage and dispensing of lubricants and coolants to the critical mobile plant in operation at the facilities.

The state-of-the-art design addresses inefficiencies in lubricant dispensing whilst achieving oil cleanliness levels of ISO 16/14/11.

Defence Industry Upgrades Ship Lifter Lubrication Systems with Viper WRL.

Supply of an Australian made Viper Wire Rope Lubrication system that can clean and lubricate the winch ropes in a single pass. With the high-performance grease pump system and specialised wire rope grease, multiple ropes are capable of being lubricated simultaneously.

This has significantly reduced labour requirements, improved the wire rope life, reduced overall maintenance costs, and ultimately improved the availability of the ship lifter.

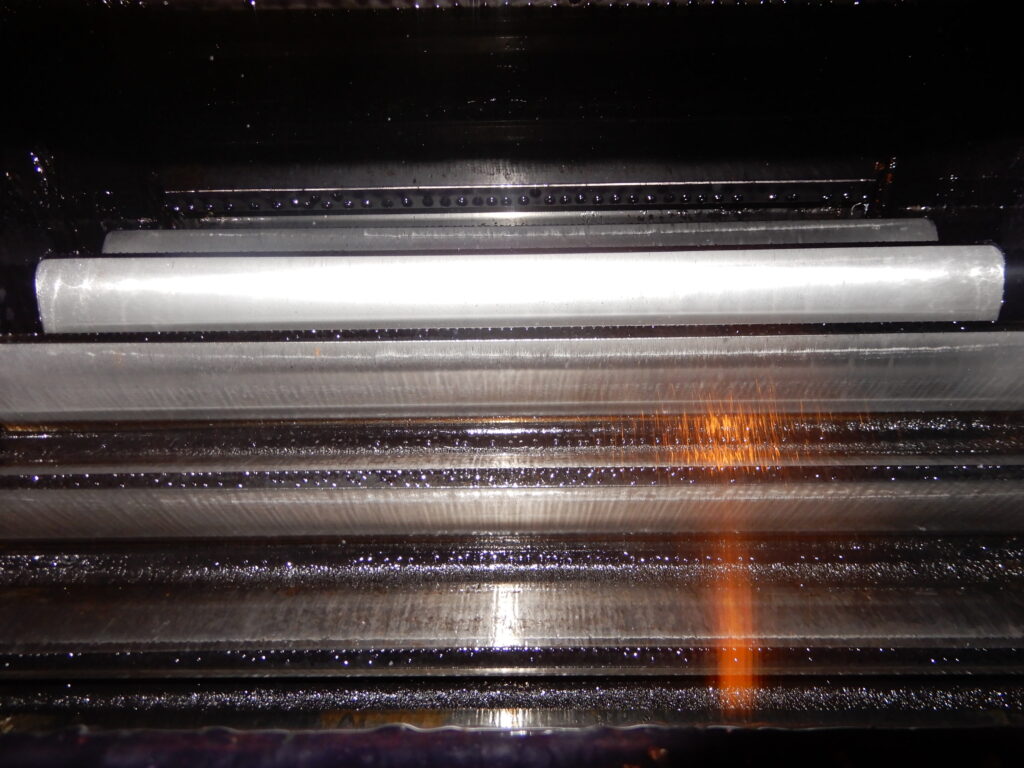

Bauxite Refinery Grinding Mill Open Gear Lubrication

Lubrication Engineering converted these Mill Open Gear systems to a high-performance open gear lubricant (LE9011 Pyroshield) as part of a detailed conversion procedure, which included refurbishment of critical automatic lubrication systems components and the flushing of the old lubricants safely, ultimately reducing the risk of failure.

Bowen Basin Coal Mine Rail Mounted Yard Machine Automatic Lubrication Systems

Design and supply of several automatic lubrication systems for five yard-machines, stacker-reclaimer, and the bucket-wheel.

The project included extensive use of CAD to design the system and the supplied custom pumping stations, providing a level of confidence at the design stage that the lubrication system had accounted for the specific needs of the site.