The M-Series automated fluid sampler from the SmartOil™ line of condition monitoring technology solutions is suitable for safely collecting LIVE fluid samples such as engine oils and hydraulic fluids from operating equipment i.e. mining haul trucks and excavators. Sample collection interval period can be programmed by the user for an automated, hands- free bottle fill event ensuring reliable contaminant-free in-service fluid is collected on time, every time.

This product is geared towards industrial and commercial applications where maintaining uptime and extending asset life of mission critical equipment is paramount.

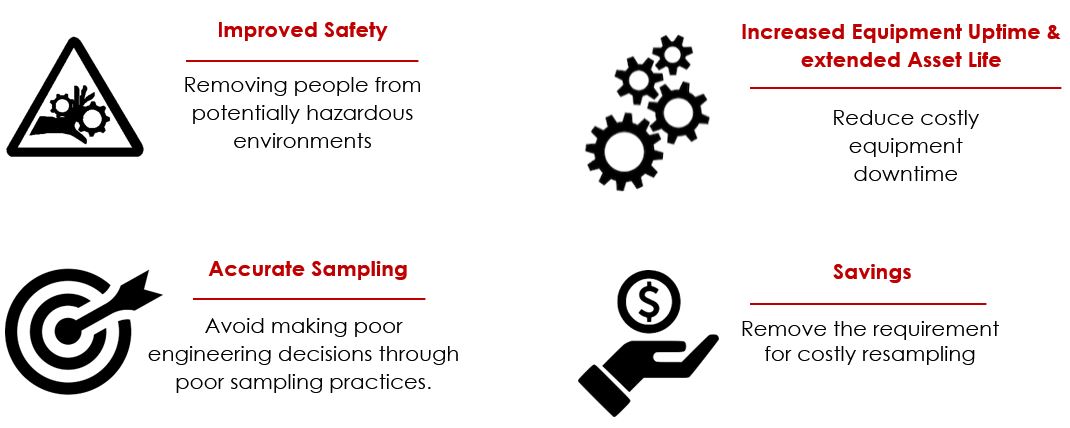

Problems we are Solving with SmartOil™ Solutions

Features

|

|

Applications

• Engines Lubricants/Coolants

• Hydraulic/Pneumatic Systems

• Pumps and Compressors

• Grinding Mills

• Gear Boxes